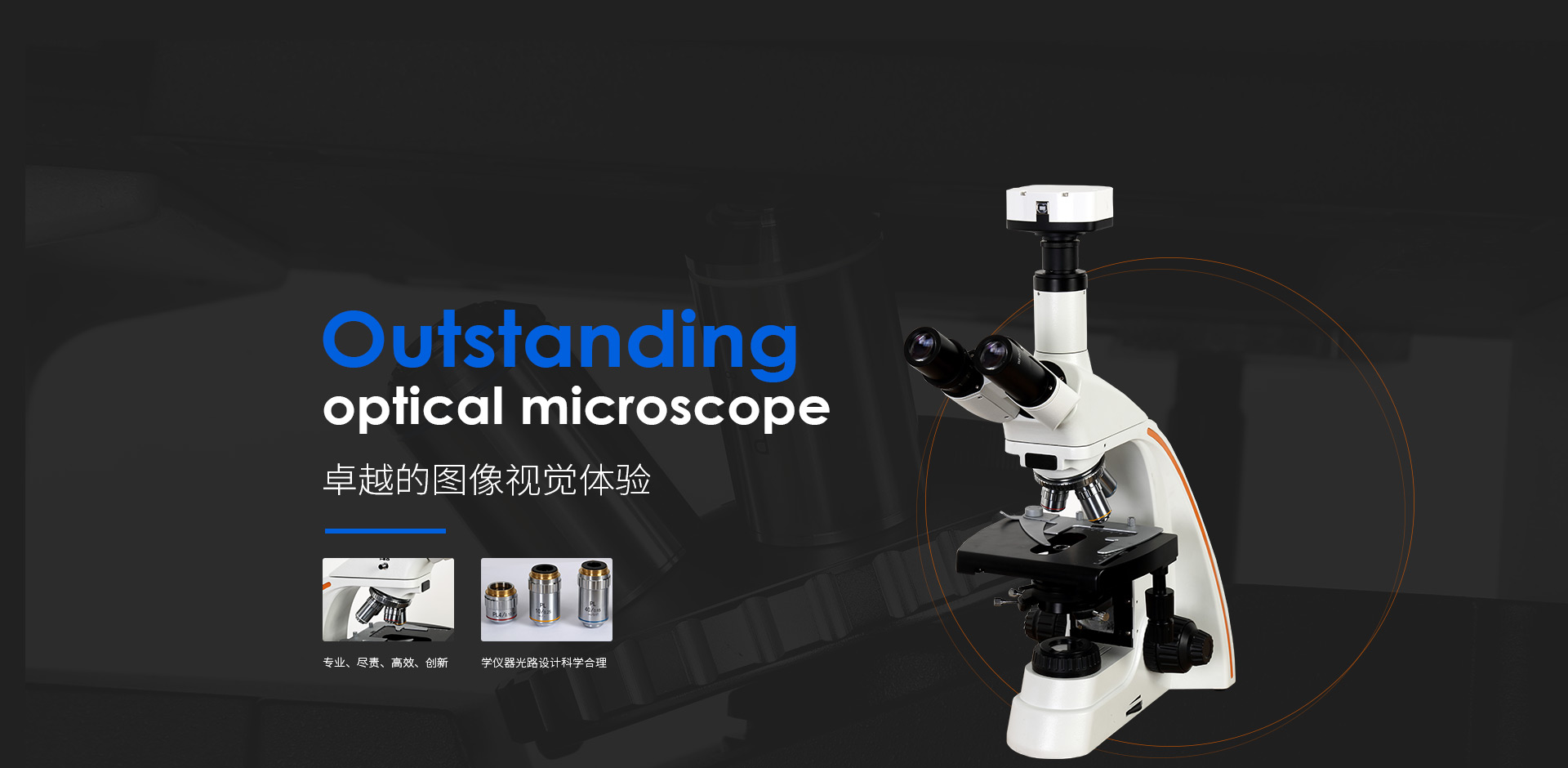

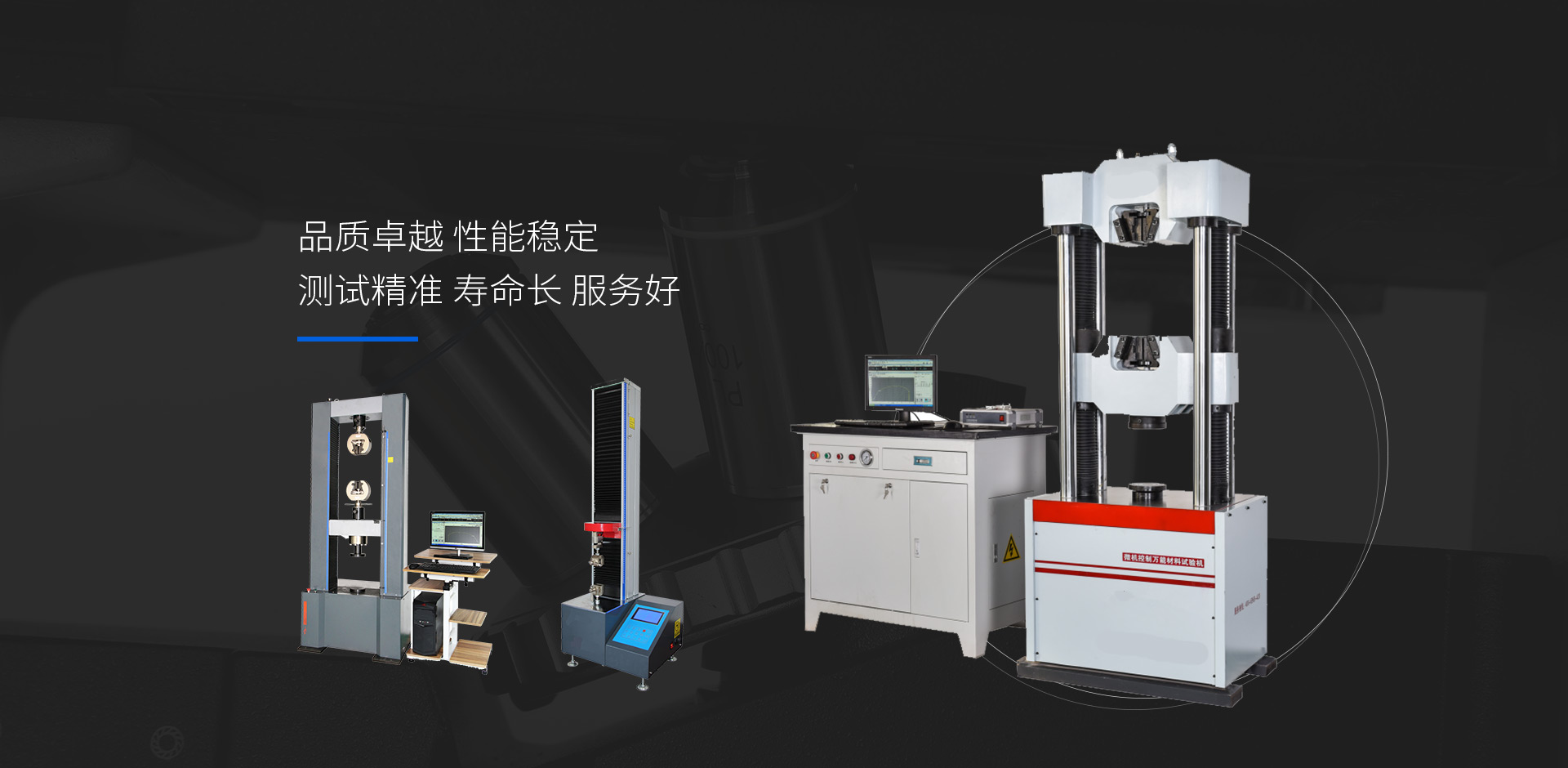

Jiangsu tuming intelligent technology Co., LTD, Predecessor shanghai tuming optical instruments Co., LTD. It is a research and development, production and sales of various industrial optical detection and analysis instruments and equipment based on micro-optics, micro-vision, digital imaging, automated measurement and non-standard intelligent detection.The company has an outstanding marketing team and technical service team to provide customers with good products and superb technical services, tailor-made intelligent optical inspection solutions. Tuming company adheres to the rigorous work attitude and pragmatic spirit of the older generation of optical industry engineers, actively innovates, and cooperates with relevant personnel in the international optical industry to jointly develop and develop new products,the optical path design of optical instruments is more scientific and more reasonable.The appearance of the instrument is concise and clear, adapting to the aesthetic needs of modern society and the trend of the international optical industry...

more+The company has consistently followed the "professional, conscientious, innovative" policy and the "prevention of pollution, strict compliance with laws and sustainable development" environmental policy, and dedication to provide domestic and foreign customers with beautiful products, excellent performance and reasonable price.…

The company has an outstanding marketing team and technical service team to tailor intelligent optical inspection solutions. Working together with relevant personnel in the international optical industry to jointly develop and develop new products, the optical path design of optical instruments is more scientific and more reasonable...

Products mainly serve the research and development of various electronic industries, communication electronics, IC chip manufacturing, LCD display technology, semiconductor packaging and testing, mobile phones and touch screens, semiconductor integrated circuits, LCD panels, solar photovoltaic...

To provide you with the equipment and equipment that suits you. According to your special needs, the company sends technicians to the site to guide the installation and commissioning of the equipment and train the operators to undertake the repair service within the three-pack period and the instruments outside the three-pack period. Equipment for professional repair and maintenance...

Tailored intelligent optical detection solutions

1. Cut the sample, first determine the sample, select the cutting machine with the correct cutting surface diameter for cutting

2. Grinding and polishing samples, according to different sample size and shape, you can choose manual grinding or automatic grinding and polishing, first sanding, sanding samples with different sand and sand, grinding to the appropriate extent (according to experience), then polishing, choose the right polishing Cloth, with a suitable diamond spray polishing solution (thickness based on experience) for polishing...

More

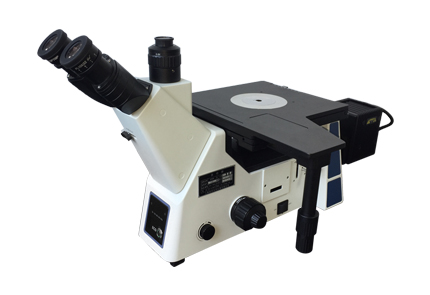

The CDM-810 uses an excellent infinity optical system and a modular functional design concept, which makes it easy to upgrade the system and achieve polarized light observation. The compact and stable high-rigidity body fully reflects the anti-vibration requirements of microscope operation. The ideal design with ergonomic requirements makes the operation more convenient and comfortable, and the space is wider. It is suitable for microscopic observation of metallographic structure and surface morphology. It is an ideal instrument for metallurgy, mineralogy and precision engineering research. Suitable for the electronics, metallurgy, chemical and instrumentation industries to observe transparent, translucent or opaque materials...

1. Cut the sample, first determine the sample, select the cutting machine with the correct cutting surface diameter for cutting

2. Grinding and polishing samples, according to different sample size and shape, you can choose manual grinding or automatic grinding and polishing, first sanding, sanding samples with different sand and sand, grinding to the appropriate extent (according to experience), then polishing, choose the right polishing Cloth, with a suitable diamond spray polishing solution (thickness based on experience) for polishing...

MoreContact:Mr. Zhang

Phone number:+0086-15800980052

Changzhou office: No. 91, hanjiang west rd., xinbei district, changzhou city, jiangsu province, china.

Factory: No.11, 255 alley, jinxiang rd., pudong, shanghai, china

SCAN IT

SCAN IT